The first thing to take into account is the flatness/planimetry of the slab. This is one of the most important points, since it must be a completely homogeneous surface without bumps or holes, as this will affect three key aspects of the installation.

-

Problems when installing the structure and glass panels

-

Problems with water drainage when it rains and the formation of puddles

-

Problems with quality of play, causing poor/irregular ball bounce

That said, when installing a padel court there are two possible solutions: using porous concrete or a semi-polished (power-troweled) concrete slab. Both options are good, but in this article we want to explain the differences and which would be the best choice in each case.

- If the court is outdoors without nearby paving: Padelmagic recommends a semi-polished concrete slab with a maximum lateral slope of 0.5% for stormwater drainage. This is an ideal option for durability, cost, and speed.

- If the court is outdoors on a fully level area or where rainwater can be collected: Padelmagic would design a porous concrete slab, maintaining the flatness and height of the entire adjacent area and ensuring optimal rainwater collection through the drainage provided by the porous surface.

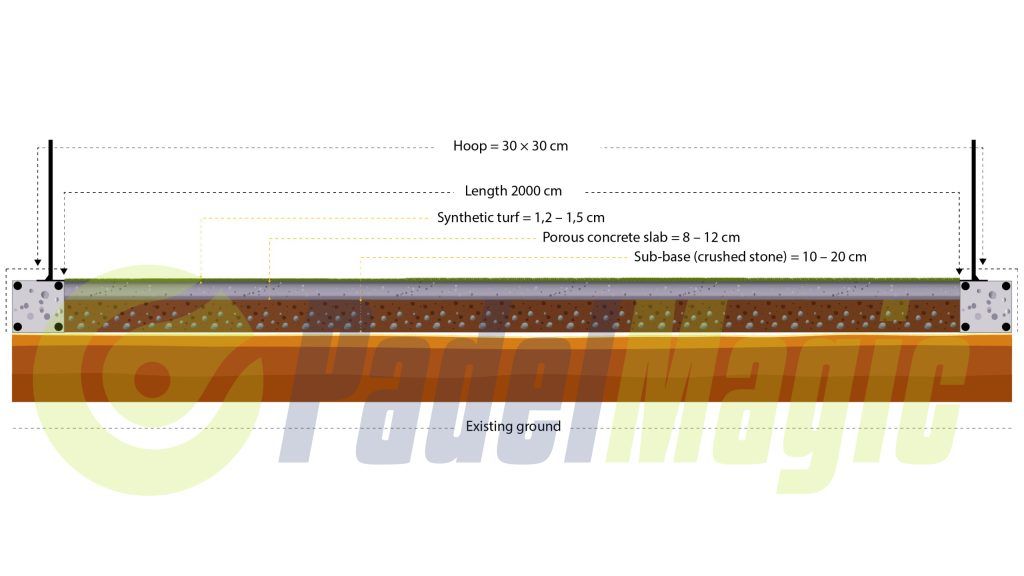

POROUS CONCRETE PADEL COURT SLAB

In the case of choosing the porous concrete option, it must include a perimeter footing (beam) where the structure will be anchored and the slab (playing area).

- The perimeter footing, where the court structure must be anchored, should be no smaller than 30×30 cm (a size of 40×40 cm is recommended) and made of foundation-grade concrete (HM-25/20MM) with the corresponding reinforcement.

Composition of the slab or playing area, from bottom to top:

− Compacted base, either natural or selected gravel (type Z2 or equivalent), compacted to 96% of the Modified Proctor density.

− Artificial gravel to form the drainage slopes.

− Concrete slab made of HM-25 concrete, with slope for water drainage.

− Drainage pipe: if the slab is built with a dual-slope design, the inclines will lead toward the sides of the court. Thus, for a 1% slope, the height difference between the highest point (central longitudinal axis of the court) and the lowest point (the sides) will be about 5 cm, which is imperceptible to players.

All these elements make up what is known as the sub-base, whose construction is essential to achieve a padel court in optimal playing conditions.

− Draining layer: 8 to 20 cm of draining gravel.

− The slab is finished with a porous pavement layer of at least 8–12 cm thickness, made on-site with selected light gravel and cement mortar, spread and leveled to achieve the necessary slopes for proper water evacuation in the case of horizontal drainage.

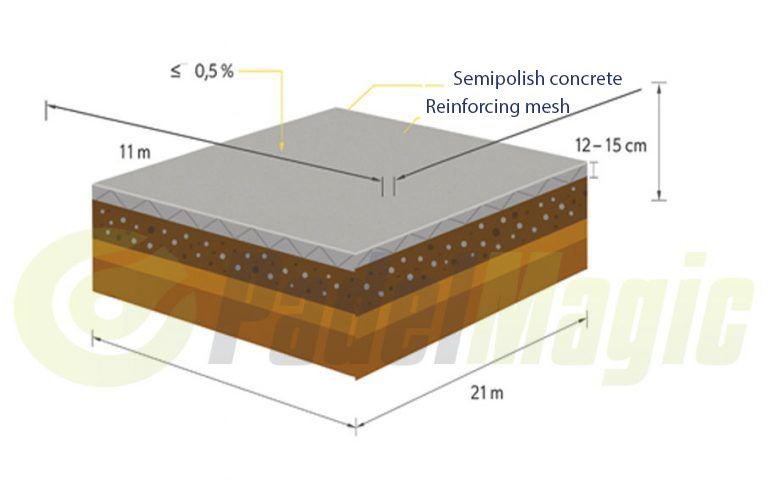

SEMI-POLISHED CONCRETE PADEL COURT SLAB

It is possible to build the slab with minimum dimensions of 21 m in length by 11 m in width, using a perimeter formwork, 6 mm reinforcement mesh or fibers, and concrete (HM-25/20MM), creating a uniform slab with an approximate thickness between 12 and 15 cm, flat and level, on which the padel court structure can be placed and anchored.

If we introduce a slope for water drainage, it should always be less than 0.5% toward one side. The final surface finish should be semi-polished with a power trowel (“helicopter”) to prevent the turf from slipping.

The lighting conduits can be embedded within the slab or run in perimeter trenches that carry the wiring to the junction/protection box, located next to the lighting poles. Any excavated trenches must be backfilled or covered with a lid to prevent falls.